No Products in the Cart

Though the technology on bicycles have changed a lot in the recent decades, most of them still use cable actuated brakes and gears. This shows how significant the need for improving the performance, costing and efficiency of cable housings. Tremendous research and technology goes in this areas and amazing innovations are made. Let's see how much detailing has done by a single company in cables alone in this article.

Brake and Shift Housing

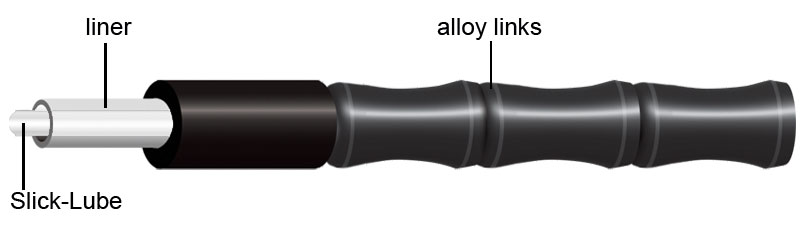

An alternative to traditional compression-less housing, this system is made of nesting alloy pieces that protect the liner. Although this housing is typically more expensive, it has several advantages including increased flexibility, reduced weight and increased durability. Both shift and brake housings use identical Slick-Lube liners and interconnecting alloy pieces.

Brake and Shift

ALLOY - interconnecting alloy links around Slick-Lube liners

Brake and Shift Housing

Jagwire sealed systems, available only in DIY kits, include liners that run continuously from the lever to the brake or derailleur. This protects the cable and housing from dirt, mud or anything else that can cause friction. But because the liner runs the full length of the cable, Ultra-Slick polished inner cables are used to keep friction to a minimum.

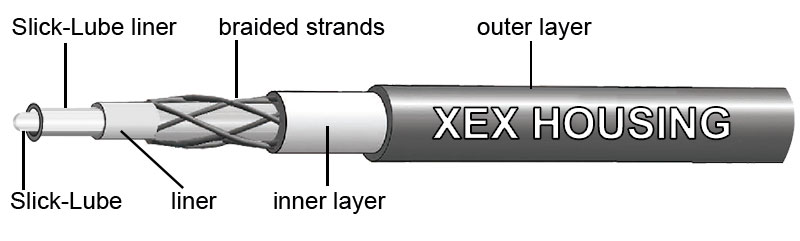

Shift

XEX - lightweight, braided steel strands around a Slick-Lube liner

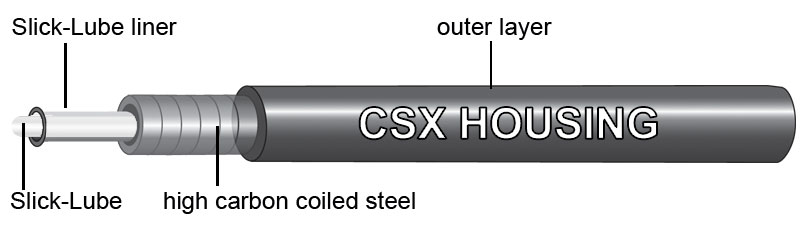

CSX - high carbon, low compression coiled steel around a Slick-Lube liner

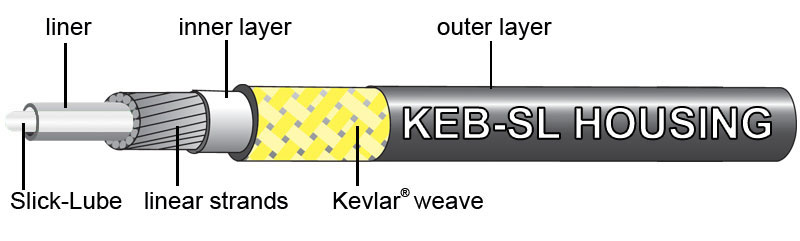

Linear Strand, Kevlar®-Reinforced, Lubricated

Brake Housing

A performance upgrade to coiled steel, this compression less housing starts with a similar construction to LEX shift housing that reduces weight by 30%. A woven Kevlar® layer is added to give the housing the strength and flexibility necessary for braking applications.

Brake

KEB-SL - linear steel strands around a Slick-Lube liner wrapped in a Kevlar®

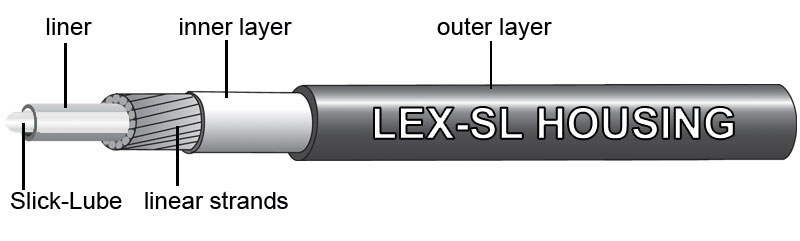

Shift Housing

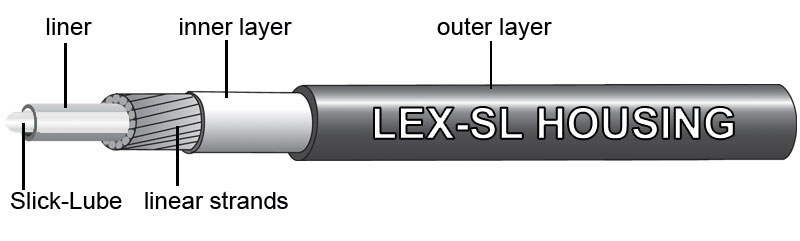

Linear strands of steel are used to encircle the Slick-Lube Liner creating a compression less ring. This delivers responsive, precise, crisp performance necessary in shift applications.

Shift

LEX-SL - linear steel strands around a Slick-Lube liner

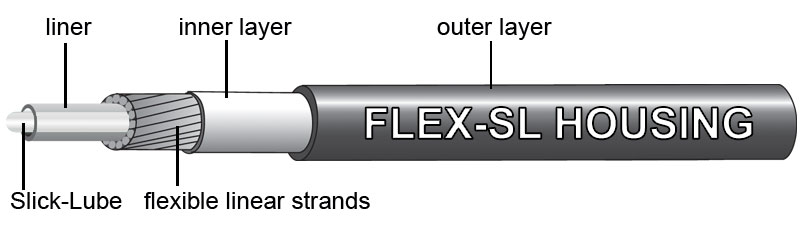

Dropper Housing

Linear strands of flexible steel are used to encircle the Slick-Lube Liner creating a low-compression ring. This makes it ideal for use with internal dropper seatposts with tight bends in the routing.

Dropper

FLEX-SL - flexible linear strands around a Slick-Lube liner

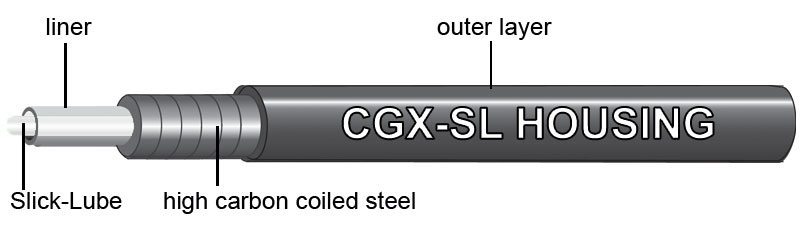

Brake Housing

No-nonsense, OE-quality brake housing using high carbon coiled steel wrapped around an inner liner. This coiled steel structure will allow some compression, but the high-quality, high carbon steel used limits the amount.

Brake

CGX-SL - high carbon, low compression coiled steel with a Slick-Lube liner

Shift Housing

Linear strands of steel are used to encircle the Slick-Lube Liner creating a compression less ring. This delivers responsive, precise, crisp performance necessary in shift applications.

Shift

LEX-SL - linear steel strands around a Slick-Lube liner

Brake Housing

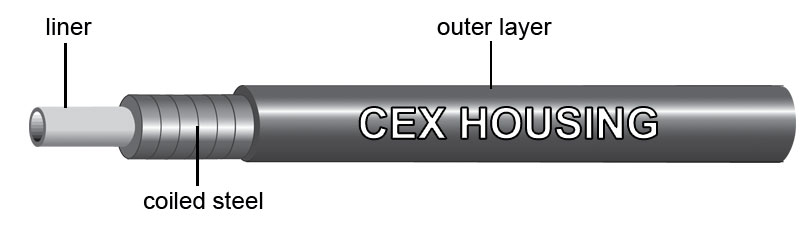

Quality, low-cost brake housing using coiled steel wrapped around an inner non-lubed liner. The combination of low cost and long-lasting performance makes it ideal for entry-level bike service.

Brake

CEX - coiled steel housing with non-lubed liner

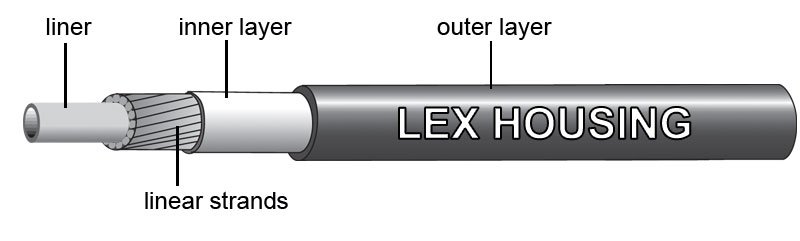

Shift Housing

Quality, low-cost shift housing using linear steel strands wrapped around an inner non-lubed liner. The combination of low cost and long-lasting performance makes it ideal for entry-level bike service.

Shift

LEX - linear steel strands around a non-lubed liner